New 3D Technology Claims To Make EV Batteries Safer

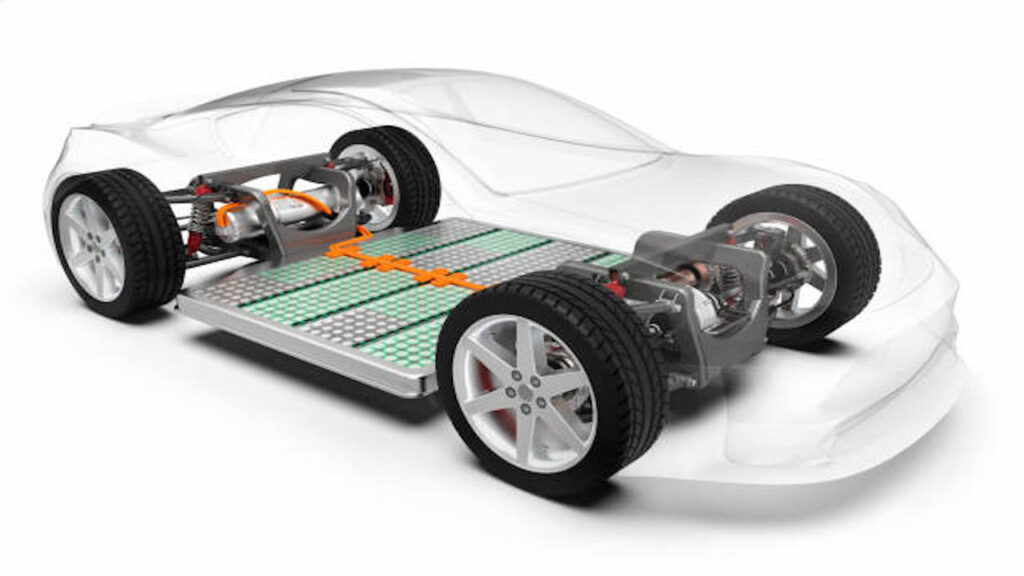

With the advent of extensive R&D in EV battery technology, new methods are being developed to address safety issues pertaining to EVs. It is becoming a trend for companies to keep devising modern methods leveraging technology to make EV batteries safer. In the last few years, many cases of terrible incidents regarding electric cars have surfaced. Unfortunately, most of these highlight some sort of battery issue as the root cause. With reports suggesting around 100 million EVs on roads worldwide by 2030, it becomes crucial to come up with solutions to make electric car batteries safer. Hence, battery companies are not just focusing on increasing range and reducing charging times, but also making them more resistant to fire and thermal runaway. We know that the latter is the biggest cause of worry. Once an EV battery catches fire, it is excruciatingly difficult to douse it. The reason is the availability of toxic and explosive chemicals in the battery construction itself. Essentially, that is a constant fuel to keep the fire going. As a result, we have had situations where the batteries kept burning for upto 48-72 hours. You might also like: Which is Better EV Battery Cooling System – Liquid or Air? You might also like: Top 5 Tips To Save / Earn Money From EV Charging 3D Thermal Barriers Technology to Make EV Batteries Safer Freudenberg Sealing Technologies, a tech company, has introduced an advanced solution to address a critical concern in the rapidly growing field of electric vehicles (EVs). The company has developed 3D thermal barriers aimed at mitigating the risk of thermal runaway in high-energy-density lithium-ion batteries, which are becoming increasingly common in modern EVs. You might also like: 5 New EV Battery Technologies – Aluminium-ion to Niobium The 3D thermal barriers mark a departure from conventional two-dimensional options like flat mats and thermal blankets. These barriers are custom, flexible, and can fit in various positions within the battery structure, allowing for easy integration of additional components. The novel 3D geometries come from injection moulding and continuous extrusion. This adaptability also offers a noteworthy advantage – the resulting intricate 3D geometries are lightweight and exert minimal impact on the overall battery weight. Freudenberg makes heat-resistant, electrical, and thermal insulating materials. Thorough in-house testing demonstrates that these materials can endure temperatures of up to 1,200°C. This resilience is due to the specific composition of the compounded polymers This renders them impervious to both extreme heat and particle impacts, such as those that occur during cell venting. The 3D thermal barriers use elastomer solutions in solid and foam forms. Additionally, they can also be plastic components like Quantix Ultra® for intricate geometric patterns. You might also like: Top Solid-State Battery Companies For EVs Learn Electric Cars Says There are new EV technologies coming about quite frequently. That is normal with so much research going on about EV batteries in various parts of the world. This may just be one of many potent ways to make EV batteries safer. With time, we expect more such breakthroughs which will have safety at its core. Not to mention, longer range and shorter charging times will still be the main parameters while designing new solutions.