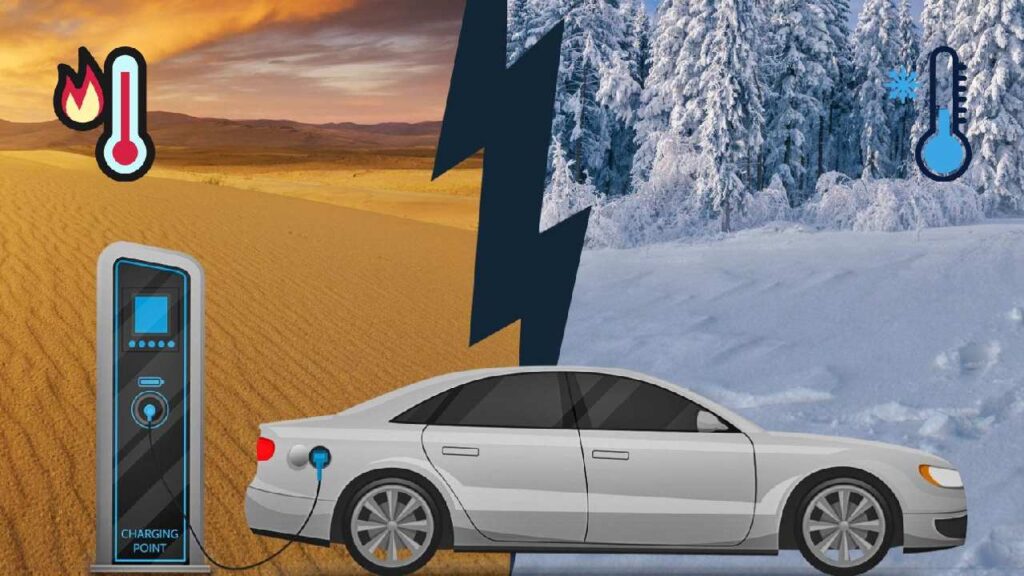

How Do Heat Pumps Function In EVs?

Heat pumps are getting more common in EVs with each passing day as we take a look at how these aid electric cars during extremely cold conditions. In this post, we shall discuss how heat pumps function in EVs in cold weather conditions. We are certain that automobile enthusiasts and EV owners must have read a lot of headlines pertaining to the extremely cold weather conditions in many parts of North America and Europe currently. Note that Lithium-ion batteries are vulnerable and sensitive to temperature changes. Hence, many EV owners are, unfortunately, stranded at homes or charging stations. While we are still not at the point where the battery technology can overcome temperature dependency, there are decent solutions in place. Heat pumps provide the best shot for EVs to tackle extreme cold environments. Sure, snowy conditions with massively low temperatures will still have an impact on EV batteries, but a large part of that impact will be eliminated by the use of heat pumps. That is the reason why so many modern EVs come with a heat pump from the factory. You may also like: New EV Battery From Zeekr To Offer 500 kW Charging How Do Heat Pumps Function In EVs? Depending on the use case, a heat pump can produce heat from any source, which could then be used anywhere in a vehicle. For EVs, it is generally used to heat the battery and make it operate within optimal temperature range, irrespective of the weather outside. Additionally, the heat produced by pumps can also provide air conditioning to warm the cabin and the passengers. Essentially, any component in an EV which requires heat can be fed via the heat pump. The heat pumps use the temperature difference between the outside air and the refrigerant to create a heating effect. In EVs, it can pull cold air from the outside and create warm air from it. This can be used to heat the cabin, which will reduce the energy consumption of the battery. Alternatively, it could also heat the battery itself, which will prepare it before plugging so that it can charge quickly. This will maximize the range. If the battery is too cold, it will take longer than usual to charge too. In fact, many reports suggest a drop in range between 15% and 45% due to cold temperature alone. You may also like: Edmunds Tests The Fastest Charging EV In Real-World Conditions EVs With Heat Pumps Many modern EVs possess heat pumps from the factory itself. Some of the top EVs include Tesla cars, Jaguar I-Pace, BMW’s latest i-series cars, Hyundai Ioniq 5 and Kona, Audi’s new e-tron, Kia EV9 and Niro, Nissan Leaf, Chevrolet Bolt, Toyota Prius, etc. This encompasses electric cars from varied price segments. Therefore, it is evident that carmakers are offering this component as standard across the range. You may also like: How Inductive / Wireless Charging Can Transform The Future Of EVs? Learn Electric Cars Says Recognizing the importance of heat pumps in EVs, car companies will carry on this trend of offering them even on budget EVs going forward. With the kind of predicament we faced with extreme cold in many parts of North America and Europe recently, the need for heat pumps in EVs is evident. EV owners were left stranded at home. Even when they towed their cars to charging stations, the chargers had frozen. They had to wait for hours to get to a charging station. Then they had to wait a lot to charge their EVs due to slow charging speeds. We can only hope that this winter will force the authorities to take this aspect into consideration while developing charging infrastructure going forward. This was also be an eye-opener for EV owners, many of whom were facing such severe conditions with their EVs for the first time ever.