New CATL Batteries To Retain 80% Capacity After 12 Years

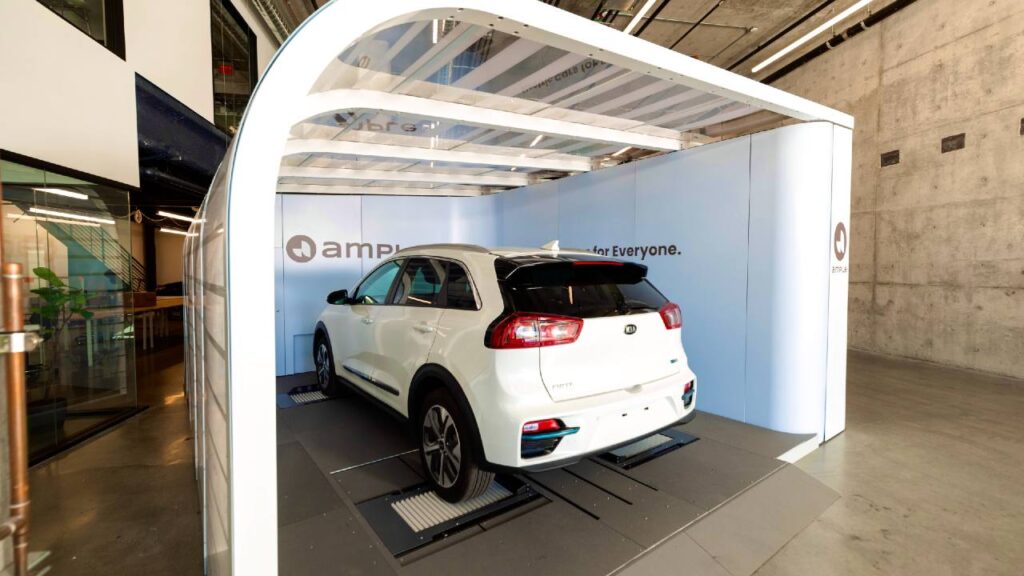

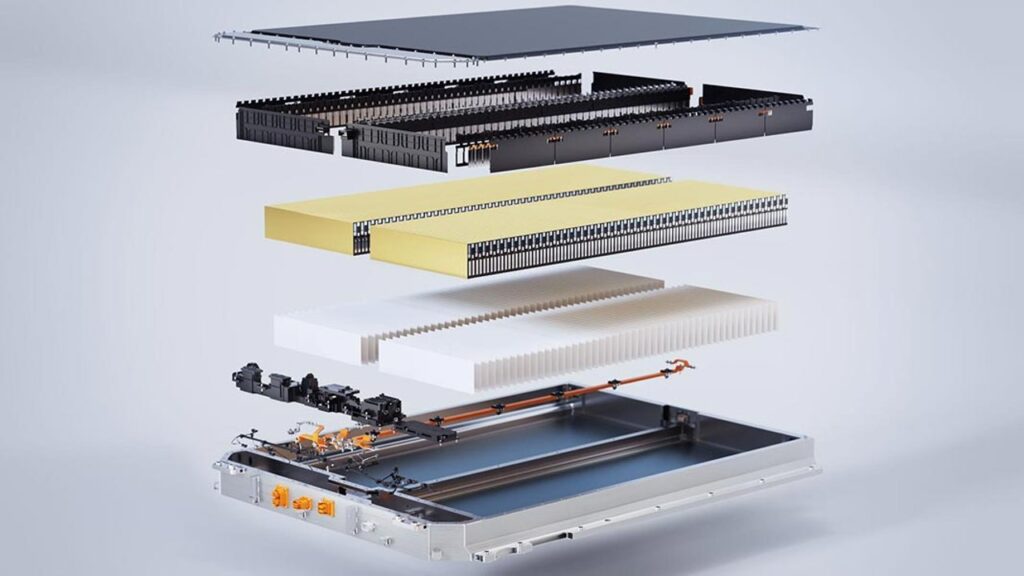

Chinese battery giant CATL and NIO have collaborated to work on new technology that will allow EV batteries to still possess 80% of capacity after 12 years of usage. As per the latest partnership with NIO and CATL, new batteries are being developed with substantially longer lifespans than the existing ones. Battery forms the single most expensive component of an electric car. In most cases, this is around 40% of the total cost of an EV. Moreover, Lithium-ion batteries have a tendency to lose capacity after usage. Hence, most carmakers offer a warranty of around 8 years. Thereafter, the battery replacement costs become a huge issue for EV owners. In order to ensure that the batteries last at least as long as the car (or approximately 10-12 years), Chinese battery giant CATL and NIO have established a partnership. They will co-develop a battery which will be able to retain 80% of its capacity even after 12 years of application. You might also like: EVs To Be Cheaper To Produce Than Gas Cars By 2027 – Study New EV Batteries From CATL and NIO NIO has created a pioneering system for keeping electric car batteries healthy. This system looks after three key factors that affect how long batteries last – temperature, how hard they’re used, and how often they’re charged. By using clever technology and a special way of swapping batteries, NIO has made sure these batteries can last a long time. Thanks to smart planning based on lots of data, NIO’s batteries can keep about 80% of their power even after being used for 12 years. Plus, NIO has worked hard to make batteries that last longer. They’ve studied the materials that make up batteries, like the stuff inside the battery that helps it work, and the liquid it’s filled with. This research has led to better batteries. NIO has become really good at all stages of creating batteries, from making the materials to testing them out. They’ve even got over a thousand patents for their technology. More than a hundred of them focus on making batteries last longer. You might also like: Next-Gen EV Batteries From Korean Giants Unveiled At InterBattery 2024 New Technology By CATL CATL and NIO also believe that between 2025 and 2030, there will be around 20 million electric vehicles which will come out of the warranty period. This doesn’t necessarily mean that the vehicles won’t be in an unusable condition. But the owners will have to shell out a bomb to replace the batteries. To tackle, that CATL has been working on innovative methods to prolong the lifecycle of EV batteries to upto 12-15 years. CATL has created new technology to make battery packs last longer. They’ve invented things like a special Solid Electrolyte Interphase film that can fix itself and add more lithium to batteries. By working together, the companies aim to build a partnership that benefits them both in the long run. These batteries will complement NIO’s battery-swapping business immensely. You might also like: Are EVs With 1000 km Range Still A Distant Reality? Learn Electric Cars Says We are still, essentially, in the first leg of the EV revolution when it comes to battery replacement. The mass-market EV sales only commenced a good couple of years ago. Hence, in the next 5-6 years, we will have millions of cases of battery replacements as the EVs run out of OEM warranty. That will be yet another major hurdle for electric cars to overcome in order to get the trust of potential EV buyers. Therefore, if there is a major breakthrough in this regard prior to that, the entire perception about EVs might change. We can only wait and see how things transpire in this case.