Nissan Sets Out to Revolutionize Its Solid-State Battery Technology

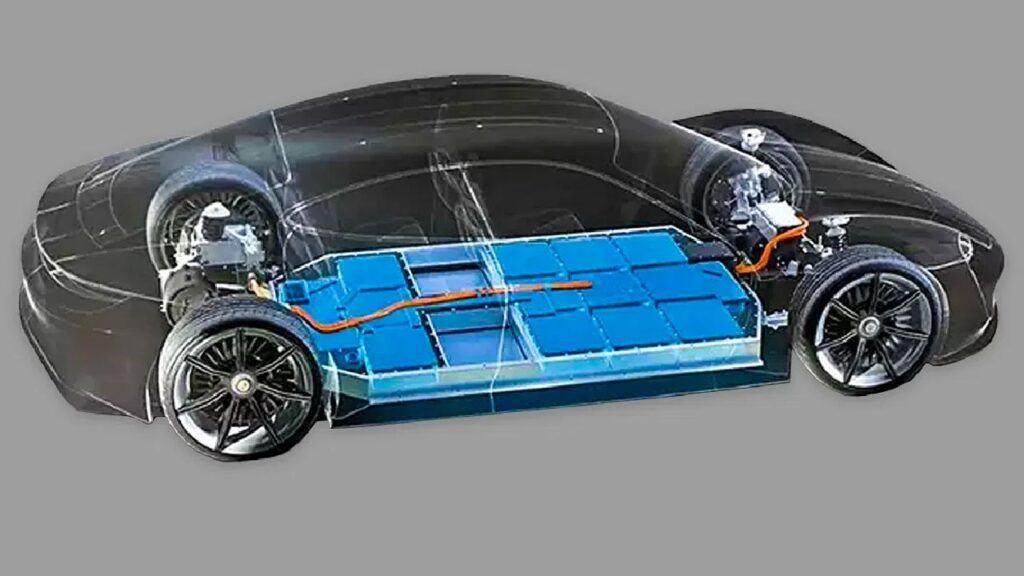

The Japanese automaker is taking giant steps toward innovative battery technology solutions to power its future EVs. In the rapidly evolving landscape of electric vehicles, Nissan is positioning itself as a trailblazer by investing in all-solid-state battery (ASSB) technology. The company envisions this innovation as a game-changer, propelling EVs into the next decade. Let’s delve into Nissan’s ambitious plans, exploring the potential benefits and challenges associated with solid-state batteries You might also like: Could Dongfeng M-Hero 917 Be Perfect Rival to Hummer EV? Leap in Battery Technology Nissan’s commitment to solid-state battery technology marks a significant leap from conventional lithium-ion cells. The company aims to double the energy density at the pack level while slashing fast charging times by two-thirds. This leap forward is not merely an incremental improvement over existing lithium-ion batteries but a revolutionary stride towards making EVs more efficient and practical. Battery Cooling Innovation One distinctive aspect of Nissan’s solid-state battery approach is its intention to eliminate the need for cooling. Unlike traditional EVs, which rely on water or air cooling systems to manage temperatures, Nissan believes that solid-state cells can withstand higher temperatures without compromising safety or performance. This unconventional strategy challenges the norm, aiming to streamline the battery design and reduce complexity, especially crucial for larger EVs like trucks, vans, and SUVs. You might also like: Ownership Experience of EVs More Tricky Than ICE Cars – Study Overcoming Challenges Nissan’s venture into solid-state battery technology reflects a learning curve from its past experiences. The company faced challenges with the cooling needs of the original battery cells in the Nissan Leaf, but subsequent advancements, including a battery chemistry change in 2015, addressed these issues. Nissan’s hands-on experience positions it uniquely in the pursuit of a cooling-free ASSB, learning from the past to drive innovation in the future. What The Future Looks Like While Nissan’s vision for solid-state batteries is promising, there are challenges to overcome. Currently seeing around 200 cycles in laboratory tests, Nissan acknowledges the longevity hurdle and plans to establish a pilot line for larger cells in 2024. The company collaborates with NASA and UC San Diego, incorporating AI techniques to address issues like lithium dendrite growth, ensuring the safety and durability of the solid-state cells. The road ahead involves fine-tuning the cells, determining the optimal chemistry, and scaling up production. Nissan Solid-State Battery Technology Nissan’s pursuit of solid-state battery technology represents a bold step towards revolutionizing the electric vehicle industry. The company’s ambitious goals, from doubling energy density to eliminating the need for cooling, indicate a commitment to pushing the boundaries of what EVs can achieve. As challenges persist and technology evolves, Nissan’s collaboration with leading institutions positions it as a key player in shaping the future of electric mobility. You might also like: How to Prevent Effects of Extreme Hot & Cold Weather on EV Batteries? Learn Electric Cars Says In a landscape where sustainability and efficiency are paramount, Nissan’s journey into solid-state battery technology holds the promise of not only enhancing the performance of larger EVs but also influencing the overall trajectory of electric vehicle development. As the automotive industry undergoes a paradigm shift towards cleaner and more sustainable solutions, Nissan’s focus on innovation underscores its dedication to providing consumers with advanced, reliable, and environmentally friendly transportation options. In conclusion, while the path to solid-state battery integration may be challenging, Nissan’s commitment to overcoming obstacles and collaborating with industry leaders indicates a future where electric vehicles are not just a viable alternative but a superior choice for a wide range of applications. As we eagerly anticipate the developments in the coming years, Nissan’s role in shaping the EV landscape is undoubtedly one to watch.