The German luxury car marque teamed up with Factorial cell engineers to install a solid-state battery in the EQS prototype for real-world testing

The Mercedes EQS becomes the first prototype from the German auto giant to test the solid-state battery in real-world conditions. We know that a lot of carmakers are focusing on this technology to power the future EVs. It is widely touted as the next big thing in the EV battery development cycle. Due to various reasons, it was limited to the lab until now. All that, it seems, is about to change.

You might also like: Hyundai Could Reveal Its ‘Game-Changing’ Solid-State Battery In March

Mercedes Tests Solid-State Battery On EQS

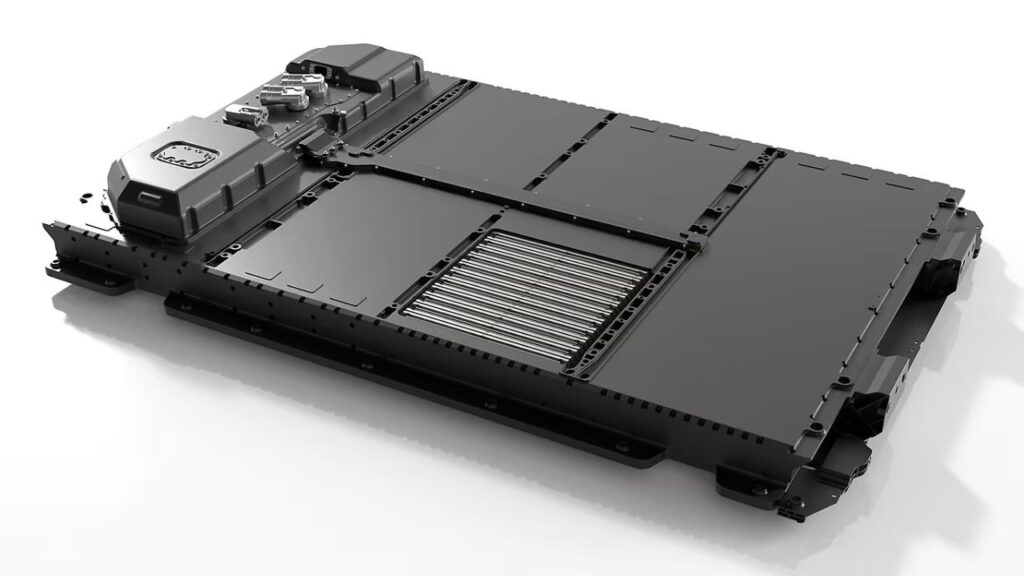

As per the official press release from Mercedes, the solid-state battery in the EQS-based vehicle allows for up to 25% more driving range compared to the same battery weight and size of a corresponding standard EQS battery. Further weight and energy efficiency are achieved through passive battery cooling. The development vehicle is expected to have a range of over 1,000 km (620 miles).

This is a consequence of the collaboration between Mercedes-Benz and Factorial Energy back in 2021. In the summer of 2024, Factorial delivered lithium-metal solid-state battery cells with the company’s proprietary FEST (Factorial Electrolyte System Technology) solid-state platforms to Mercedes Benz, which marked the first lithium-metal solid-state battery B sample shipment to a global OEM.

The Mercedes EQS was slightly modified to integrate the solid-state battery for road tests. These batteries use a solid electrolyte which enhances cell safety and allows for the use of new anodes like lithium metal. This ensures that they outperform conventional lithium-ion cells. Moreover, they also enable next-level energy densities, in combination with a lithium-metal anode. The solid-state technology has the potential to increase the gravimetric energy density for vehicle batteries up to 450 Wh/kg at the cell level and thereby increasing the driving range.

Gravimetric energy density refers to the amount of energy stored in a battery cell per unit mass. This metric is crucial for evaluating the efficiency and performance of battery cells. Mercedes-Benz CTO, Markus Schäfer, said, “Developing an automotive-scale solid-state battery underlines our commitment to innovation and sustainability. We’re therefore excited to announce that we’ve started road testing with a prototype vehicle equipped with this advanced technology. We will gain crucial insights into possible series integration of this cutting-edge battery technology.”

Similarly, Factorial Energy CEO and Co-Founder, Siyu Huang, remarked, “Being the first to successfully integrate lithium metal solid-state batteries into a production vehicle platform marks a historic achievement in electric mobility. This breakthrough demonstrates that solid-state battery technology has moved beyond the laboratory and into real-world application, setting a new benchmark for the entire automotive industry. Our collaboration with Mercedes-Benz proves that the future of electric vehicles is not just a vision, but a reality we’re delivering today.”

You might also like: Honda To Launch Solid-State EV Batteries With 620 Miles Of Range

Learn Electric Cars Says

The solid-state battery technology has been experimented with for a long time now. However, in the last couple of years, major auto companies have been focusing on them. We hear the plans for mass production in the latter half of the decade. However, it is becoming more certain that among many new technologies sprouting up every week, the solid-state battery tech seems the most likely to stay. We shall have to wait to see how things shape up.

Pingback: Fastest Mercedes AMG Will Be Electric, Debut This Year